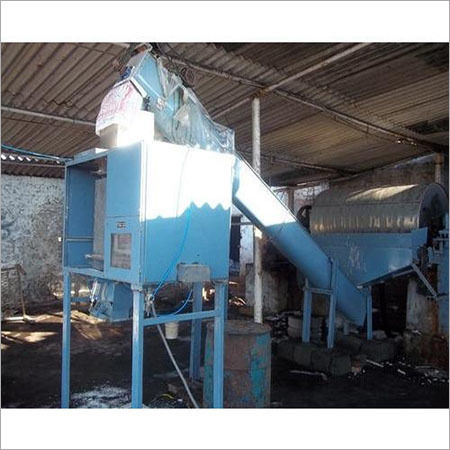

Powder Packaging Machine

468000 INR/Unit

Product Details:

- Input Power 250 Watt (W)

- Machines Type Forming,Filling,Sealing

- Driven Type Electric

- Automatic Grade Semi-Automatic

- Voltage 440 Volt (v)

- Click to view more

X

Powder Packaging Machine Price

- 1 Unit

- 468000 INR/Unit

Powder Packaging Machines Specification

- Electric

- Forming,Filling,Sealing

- Semi-Automatic

- 250 Watt (W)

- 440 Volt (v)

Powder Packaging Machine Trade Information

- Ahmedaabd

- Cash Advance (CA) Letter of Credit (L/C) Cash in Advance (CID) Cheque

- 20-25 Unit Per Month

- 1 Week

- Yes

- standard packing

- Asia Australia Africa

- All India

- iso certified

Product Description

Our organization is regarded as a chief manufacturer and supplier of a wide gamut of Powder Packaging Machine. This range is suitable for packing of different powder forms, thus widely praised in different industries. It is manufactured in accordance with international industrial norms by choosing a premium grade of components that work together with upgraded machine under the regular check of our experts. Powder Packaging Machine is obtainable by our clients in numerous specifications at nominal prices to meet their changing requirements.

Powder Packaging Machines are in high demand across a wide range of industries, notably in the food, pharmaceutical, chemical, and cosmetic industries. These machines are critical in the effective packing of a broad variety of powdered items, including spices, wheat, milk powder, medicinal powders, detergent powders, and cosmetic powders.

Suitable for packing 25 kg, 30 kg and 50 kg material in Jute or LDP bags

Features of Powder Packaging Machines

- The machine ensures homogeneity in each container by accurately and consistently dosing powdered goods.

- The machine can handle a broad variety of powdered materials, accommodating various package kinds and sizes.

- Powder Packaging Machine is intended to keep a clean atmosphere, avoid contamination, and ensure product safety.

Technical Specifications: Powder Packaging Machines

- Forming Function: Forming, Filling, Sealing

- Material Type: Powder

- Packaging Material: Composite Materials

- Packing Speed: 4000 Bag/Hours

Get a Close Look at Powder Packaging Machine

FAQs : Powder Packaging Machines

Is it simple to use a Powder Packaging Machine?

Yes, most Powder Packaging Machines include user-friendly interfaces and straightforward controls, making them simple to use and allowing for rapid operator training.

How does a Powder Packaging Machine keep the packaging process clean?

Powder Packaging Machines are built with sanitary features including dust control systems and easy-to-clean surfaces to avoid contamination and assure powder safety.

Powder Packaging Machines employ what sorts of sealing methods?

Powder Packaging Machines utilize different sealing techniques, such as heat sealing, impulse sealing, and continuous band sealing, based on the packaging material and specific product requirements.

Enter Buying Requirement Details

Other Products in 'Bag Packing Machine' category

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |