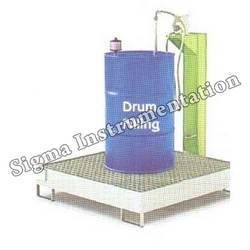

Tin Oil Packaging Machine

Product Details:

- Product Type Tin Oil Packaging Machine

- Material Mild Steel

- Application Chemical Food

- Packaging Material Plastic Glass Metal

- Automatic Grade Semi-Automatic

- Drive Type Electric

- Feature ECO Friendly High Efficiency Simple Control

- Click to view more

Tin Oil Packaging Machine Price And Quantity

- 1 Unit

- 108000 INR/Unit

Tin Oil Packaging Machine Product Specifications

- Tin Oil Packaging Machine

- Chemical Food

- Semi-Automatic

- Mild Steel

- Electric

- Plastic Glass Metal

- ECO Friendly High Efficiency Simple Control

Tin Oil Packaging Machine Trade Information

- 20 Unit Per Month

- 1 Week

Product Description

Our company is known as one of the leading manufacturers and suppliers of heavy-duty Tin Oil Packaging Machine that is in high demand due to high robustness and quick oil filling capabilities. It is commonly used in oil production industries for efficient of tin cans. The machine is in high demand due to its robust design, simple user interface, low power consumption, and longer service life. It comes with an inbuilt weighing mechanism to measure the weight of can during filling process that helps to prevent overfilling. It is provided with a smart and intelligent control panel to easily set operational parameters. Customers can get this highly productive filling machines as per their demands at a reasonable and low price.

- Consistent filling with zero risk of material wastage.

- Suitable for different-sized tin containers.

- Automated capping and sealing mechanism.

- Simple-to-use automated control panel to ensure controlled operation.

- Reliable safety units such as sensors, emergency stop buttons, and interlocking systems protect the operator as well as the machine.

- High filling speed makes it suitable for small to large-scale industries.

- Compatible with various types of oil of different viscosities.

- Made up of food-grade materials that offer high cleanliness.

- High energy efficiency which results in reduced operational costs.

Application:

- Milk, Oil, Lassi, Flavored Drink, Water etc.

Packaging Range:

- 200-1000 ml

Specifications:

- Automatic Grade: Automatic

- Type: Forming Filling Sealing Machine

- Forming Function: Seal

- Material Type: Solid

- Packaging Material: Film

Technical Specifications:

- Automatic Grade: Automatic

- Type: Forming Filling Sealing Machine

- Forming Function: Seal

- Material Type: Solid

- Packaging Material: Film

Specification

|

Filling System |

Volumetric |

|

Power |

20-30 kW |

|

Brand |

Sigma |

|

Capacity |

5Kg to 15Kg |

|

Machine Type |

Manual, Semi-Automatic |

|

Material |

Mild Steel |

FAQs: Tin Oil Packaging Machine

How does a Tin Oil Packaging Machine work?

The general process of Tin Oil Packaging Machine working involves the following steps:

- Selection and placement of Container Placement: Select the right size of the container that needs to be filled and place it at the filling line.

- Filling: When the tin container is placed in the right place, the filling mechanism is actuated to transfer oil from the reservoir tank to the filling nozzle for efficient filling of containers.

- Sealing: After the filling process, the open top is sealed with a lid or cap to make a secured seal for the prevention of oil spillage.

- Quality Control: When the cycle is completed, the filled container is then transferred to the inspection system to find any defects and abnormalities.

List the advantages of a Tin Oil Packaging Machine.

A Tin Oil Packaging Machine offers several advantages within small to large-scale industries:

- The automated process of this machine ensures efficient and controlled operation making it suitable for large-scale production.

- Offers excellent consistency during filling, packaging, and sealing to deliver high-quality products.

- The high filling accuracy of this machine ensures zero risk of oil wastage.

- Ensure higher levels of hygiene due to its automated operation.

- Low power consumption and less service requirement.

- Compatibility with different-sized containers.

How do I maintain a Tin Oil Packaging Machine?

Given below are the guidelines that need to follow to maintain Tin Oil Packaging Machine:

- Go through the manual that needs before working on a machine to eliminate the risk of accidents.

- Perform regular cleaning of the machine and other components to remove impurities such as debris, dust, and dirt.

- Application of lubrication to mechanical components to enhance the service life of moving parts.

- Inspect and replace damaged components to ensure high safety.

- Perform scheduled maintenance to improve the service life of the machine.

- Train the operators for efficient and controlled operation.

How do I choose the right Tin Oil Packaging Machine for my needs?

While choosing the right Tin Oil Packaging Machine it is advised to consider the following factors:

- Determine the production requirements of your industries, this helps to select the machine with the right production capacity.

- Decide the automation level you require for your industry to meet the production capacity of your industry.

- Consider machines that are capable to handle different-sized containers.

- The filling mechanism of this needs to be fully automated in operation to ensure accurate and precise filling.

- The components of this machine should be manufactured by using top-grade engineering materials that provide high durability and strength in extreme industrial conditions.

- Select the machine that can be easily integrated with other machines.

Other Products in 'Liquid Filling System' category

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |