Bulk Bag Filling System

Price 488000 INR/ Unit

Bulk Bag Filling System Specification

- Automatic Grade

- Automatic

- Packaging Material

- Plastic

- Machines Type

- Manual

- Voltage

- 440 Volt (v)

- Material

- M.S. and S.S.

- Filling Capacity

- 10-12 Kg/hr

Bulk Bag Filling System Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedaabd

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- standard packing

- Main Export Market(s)

- Australia, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- iso certified

About Bulk Bag Filling System

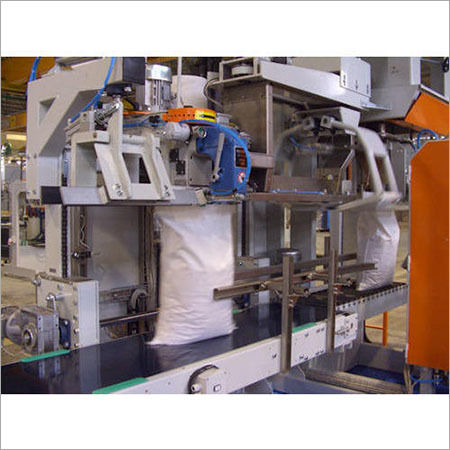

Bulk Bag Filling System

The Bulk Bag Filling System is a specific equipment which can fill large bulk bags competently and safely. It fills the bag, occupied with several bulk materials such as granules, powders, and other solid products. The said system is commonly suited for many industries such as agriculture, food processing, mining, chemicals, pharmaceuticals, construction, etc. The said machine can simplify the process of transporting bulk materials from storage to the packaging phase. Bulk Bag Filling System can make reduction in manual labor and evade the risk of spillage or contamination.

Features of Bulk Bag Filling System:

-

Made from strong material and parts

-

Simple to maintain and clean

-

Save on high labor costs and boost overall productivity, resulting in inclusive cost savings

-

Durable and reliable

Technical Specifications:

-

Forming Species: Bag Moulding

-

Driven Type: Pneumatic

-

Packaging: Bag

-

Material: The Part Contact Material Is Stainless Steel

-

Capacity: 10-12 BPH

-

Usage/Application: Industrial

-

Power Consumption: 440 V AC

-

Machine Type: Manual

-

Brand: SIGMA

-

Material: M.S. and S.S.

-

Dimension: 4 x 4 x 10 Ft

-

Filling Valve Head: 300 mm dia

FAQs: Bulk Bag Filling System

Q: What sort of materials can be filled using the Bulk Bag Filling System?

A: Bulk Bag Filling System is suited for filling assorted types of materials such as cement, chemicals, fertilizers, minerals, grains, and food products.

Q: What are the advantages of using Bulk Bag Filling Systems?

A: There are several advantages of using the Bulk Bag Filling Systems such as reduced labor costs, improved product handling, high efficiency, smart utilization of storage space, minimized contamination risk, etc.

Q: Are Bulk Bag Filling Systems customizable?

A: Almost all manufacturers provide customization options to run into specific application requirements. Customizations can be done in several orbits such as filling rates, bag handling features, weighing systems, and incorporation with current production lines.

Q: What safety features must be included in a Bulk Bag Filling System?

A: Important safety features of the machine are safety interlocks, overload protection, and dust containment systems to prevent operation when the bag is in incorrect position, overload protection, and lessen the occurrence of airborne particles.

FAQs of Bulk Bag Filling System:

Q: What is the filling capacity of the Bulk Bag Filling System?

A: The Bulk Bag Filling System has a filling capacity of 10-12 Kg/hr.Q: What type of materials can the system handle for packaging?

A: The system is designed to work with plastic packaging materials.Q: Is the system manual or automatic?

A: The Bulk Bag Filling System is automatic but includes manual machine operation.Q: What materials are used to construct the Bulk Bag Filling System?

A: The system is made using M.S. (Mild Steel) and S.S. (Stainless Steel).Q: What voltage does the Bulk Bag Filling System operate on?

A: The system operates on 440 Volt (v).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bagging System Category

Jumbo Bag Packaging Machine

Price 468000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Packaging Machine

Voltage : 230 Volt (v)

Material : M.S. and S.S.

Automatic Bag Filling System

Price 3725000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Automatic Bag Filling System

Driven Type : Electric

Jumbo Bagging Machine

Price 456000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Jumbo Bagging Machine

Voltage : 440 Volt (v)

Material : M.S. and S.S.

Driven Type : Electric

Bulk Bagging Systems

Price 468000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Bulk Bagging Systems

Voltage : 400 Volt (v)

Material : Mild Steel

Driven Type : Electric

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry