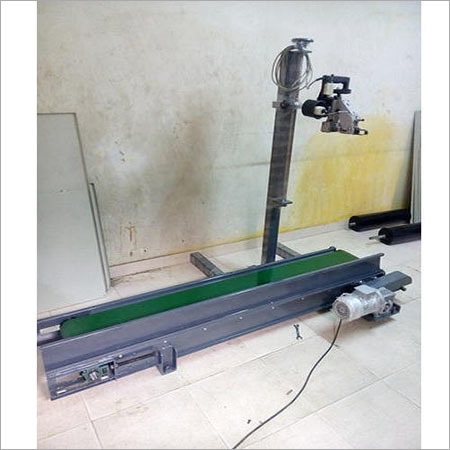

Filled Bag Closing System

Price 144000 INR/ Unit

Filled Bag Closing System Specification

- Product Type

- Filled Bag Closing System

- General Use

- Packaging Industry

- Capacity

- 6 - 10 bags/minute

- Weight (kg)

- 300 kg

- Automatic Grade

- Automatic

- Type

- Bag Closing Machine

- Drive Type

- Motorized

- Bag Type

- PP, HDPE, Jute, Kraft Paper Bags

- Computerized

- No

- Power

- 0.75 kW

- Voltage

- 400 Volt (v)

- Heater

- Yes

- Material

- Mild Steel

- Dimension (L*W*H)

- 1200 x 700 x 1600 mm

- Color

- Blue/Grey

- Stitching Type

- Single or Double Thread

- Height Adjustment

- Manual / Motorized

- Conveyor Included

- Yes

- Noise Level

- Low

- Stitching Material

- Polyester Thread

- Sealing Speed

- Up to 12 meters/minute

- Control Panel

- Digital

Filled Bag Closing System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Export Market(s)

- Asia, Australia, Africa

- Main Domestic Market

- All India

About Filled Bag Closing System

A filled bag closing system is a machine used to seal and close bags that have been filled with a product, such as food items, seeds, or chemicals. The system typically consists of a bag closing machine, a conveyor belt, and a bag sewing or sealing machine.The bag closing machine is used to feed the bags onto the conveyor belt, which then transports the bags to the sewing or sealing machine. The sewing or sealing machine then closes and seals the bags to prevent the product from spilling out.

There are different types of bag closing systems available, including manual, semi-automatic, and fully automatic systems. In manual systems, operators manually feed the bags into the machine and then manually close and seal them. Semi-automatic systems use a combination of manual and automated processes, while fully automatic systems are entirely automated and require little to no operator intervention.

Some bag closing systems use sewing machines to stitch the bags closed, while others use heat sealing technology to melt and seal the bags shut. The choice of technology depends on the product being packaged and the desired level of protection needed.Overall, a filled bag closing system is an essential piece of equipment for packaging facilities that need to seal and close bags filled with various products efficiently and effectively.

Technical Details of Filled Bag Closing System

- Series: Sliding Door System

- Glass Thickness: 8-12mm

- Inside Package: Bubble Bags with Strong Carton Protect

Efficient and Versatile Bag Closing Solution

Engineered for the packaging industry, this Filled Bag Closing System integrates speed, reliability, and adaptability. The machine accommodates various bag materials, such as PP, HDPE, jute, and kraft paper, supporting different industrial requirements. Its digital controls, height adjustment options, and noise reduction design make it an optimal choice for high-volume operations, ensuring both operator comfort and productivity.

Robust Construction and Seamless Operation

Constructed with mild steel and finished in blue/grey, the machine easily withstands intensive industrial use. Its motorized drive, integrated conveyor, and polyester thread work in tandem to deliver consistent, secure stitching. Additionally, the machine's dimensions and moderate weight allow for efficient integration into most packaging lines, while its low power consumption offers cost-effective performance.

FAQ's of Filled Bag Closing System:

Q: How does the Filled Bag Closing System operate during the packaging process?

A: The system automatically conveys filled bags, adjusts their height (manually or motorized), and securely closes them using durable polyester thread. Operators set desired parameters on the digital control panel, allowing the machine to stitch each bag with single or double thread at a speed of up to 12 meters per minute, and seal 6-10 bags per minute efficiently.Q: What types of bags can this machine handle in industrial settings?

A: This bag closing system is designed to work with a variety of materials including polypropylene (PP), high-density polyethylene (HDPE), jute, and kraft paper bags, making it highly versatile for diverse packaging applications in industries such as agriculture, food processing, and bulk commodities.Q: When is it beneficial to use single versus double thread stitching?

A: Single thread stitching is generally suitable for lighter loads or short-term storage, providing adequate seam strength. Double thread stitching offers greater security and durability, ideal for heavier bags or when products require longer transportation or storage periods.Q: Where can this bag closing system be integrated within a packaging facility?

A: With its compact dimensions (1200 x 700 x 1600 mm) and included motorized conveyor, this machine can be seamlessly installed at the end of any automated or semi-automated filling line in factories, warehouses, or packaging plants, enhancing workflow efficiency.Q: What is the process for adjusting the machine for different bag sizes or materials?

A: The machine's height can be adjusted either manually or via a motorized mechanism to accommodate bags of varying sizes. Operators can also set stitching parameters through the digital control panel to ensure compatibility with different bag thicknesses, ensuring a secure closure every time.Q: How does the low noise level benefit production environments?

A: Operating with minimal noise, this bag closing machine contributes to a quieter workplace, reducing operator fatigue and meeting industrial regulations for noise control. This creates a safer, more comfortable environment for workers during extended packaging operations.Q: What are the main advantages of using this bag closing system for exporters and manufacturers?

A: The system enables fast, reliable, and uniform sealing of bulk bags, improving productivity and reducing manual labor costs. Its robust design, consistent stitching quality, and flexibility for multiple bag types support large-scale operations and enhance the professional presentation of export-ready packaging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Stitching Machine Category

Bag Stitching Belt Conveyor

Price 225000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Packaging Industry

Voltage : 230 Volt (v)

Product Type : Bag Stitching Belt Conveyor

Color : Blue & Silver

Conveyorised Bag Stitching Machine

Price 125000.00 INR / Unit

Minimum Order Quantity : 2 Units

General Use : Industrial

Voltage : 230240 V Volt (v)

Product Type : Conveyorised Bag Stitching Machine

Color : Blue & Silver

Conveyor Bag Closing Machine

Price 144000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Packaging Industry

Voltage : 400 Volt (v)

Product Type : Conveyor Bag Closing Machine

Color : Green / Blue

Bag Filling Machine with Stitching

Price 588000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Voltage : 400 Volt (v)

Product Type : Bag Filling Machine with Stitching

|

SIGMA INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry